US research darkest material can absorb 99% of light

Recently, NASA engineers successfully developed a special material which can achieve the ultraviolet, visible, infrared and far-infrared light for more than 99% absorption rate. The emergence of this technology is expected to open the frontier of space exploration.

A team of engineers at NASA's Goddard Space Flight Center in SPIE Optics & Photonics conference held recently done a related report. This is the industry's largest interdisciplinary technical meeting. According to the 10 who developed the technology team leader John Goddard engineers (John Hagopian) said they then also on the absorption properties of the new materials were additional confirmatory testing to verify its effectiveness.

He said: "reflex tests show we have successfully developed material properties of the material will absorb more than 50 times before lifting the team also developed a near perfect absorption properties of the material, but their material only in a narrow band, such as UV. effective and visible light, and our material is to achieve absorption from UV up to the full band far-infrared, which is unprecedented. "

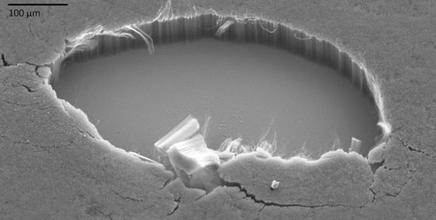

The nature of this material is a multilayer coating of carbon nanotubes, which is pure carbon tubular body consisting of a hollow, the thickness of a human hair in diameter than 10,000 times smaller. They attached perpendicular to the surface of different substrate materials, like wool carpet. Engineers team has tested these materials attached to the surface of silicon, silicon nitride, titanium and stainless steel, these are commonly used in space engineering materials. In order to allow the smooth attachment of carbon nanotubes, engineers Goddard Flight Center(Stephanie Getty) on the surface of the test material coated with iron catalyst coating. She then the material is heated to 750 degrees Celsius, while being exposed to the carbon material gas environment.

Tests show that this material in many fields have a very good space applications, especially when the science mission needs to be more multi-band observations will show its importance. One important application is the stray light suppression. Attached to the material can be collected at the surface of carbon nanotubes and block the background light, thereby preventing it reflected off the surface, and then between scientists need objective observation light interference. It is because only a very small portion of the light can be reflected away, so in the human eye, even sensitive instruments view, this material is black.

In particular, the Panel found that the material in the ultraviolet and visible wavelengths of light absorption rate of 99.5%, while in the longer wavelength band and far infrared absorption rate has reached 98 percent. Hagopian said: "Compared to our advantage over other materials, this material is its absorption rate which is higher than 10 to 100 times, depending on the performance of specific bands."

Goddard engineers (Manuel Quijada) is one of the co-authors of the paper, he said: "Our results for such a little surprised that we know that it can absorb the light, but we did not expect it would be so good absorption properties.."

Once the material is put into use, it will greatly enhance the performance of detectors and devices. For example, this technology will allow scientists to detect very distant universe, its light and even has a weak signal undetectable in the visible celestial bodies, or of celestial bodies in high-contrast environments, such as around other stars, running faint planetary observation. And study the Earth's atmosphere and oceans, scientists also will benefit. Earth observation equipment received optical signal 90% of atmospheric scattering reflections of "stray light", thereby covering the surface reflection signal they want observations.

Under current conditions, the engineers will use the black coating, or by means of other auxiliary equipment to help reduce stray light interference. However, black can only absorb about 99% of the incident light, and multilayer reflective coating carbon nanotubes are produced to make the material more superior overall performance, and even be able to reduce stray light more than 100 times.

It is also important, as Ed Goddard engineers (Ed Wollack) pointed out, is painted black at extremely low temperatures will no longer be black. They will show a sparkling silver tone.Wollack responsible for ultra-low temperature properties of this material for testing, designed to test their suitability for use in ultra-sensitive far-infrared detection device, the device operates in ultra-low temperature environment for receiving emanating from the depths of the very distant Universe faint far-infrared signals. If these devices are not enough, "cooling", the infrared radiation device and the heat generated by the telescope itself will disturb and weaken the sensitivity of the device.

• Goddard engineer Jim Tuttle said that the black material in the spacecraft equipment as well as an important application, especially for infrared detection equipment is concerned more so. Materials more "black", it will be able to radiate more heat. In other words, super-black material, such as carbon nanotubes can be used to coat the device needs to be removed at ambient temperature, it can help distribute the heat into outer space. This will help ensure that the cooling device, thus ensuring for faint deep-sky objects keen to capture the signal.

In order to prevent the absorption performance is not an ideal situation long black paint appeared on the band, engineers will use the epoxy resin with a conductive metal material, thereby making a black film. Although the effect of this material is acceptable, but it will increase the weight of the spacecraft, which makes technical staff are very troubled. And once you have this new carbon nanotube coating material, which density is smaller, but superior performance, no additives, each band can efficiently absorb light and effective heat dissipation.Wollack said: "This will be a very promising material that is very effective, very light weight, and exhibit extreme black in the long run, than the black paint performance to be better..."

- Pre:May 2014-May 2015 the leather 2015/8/23

- Next:Synthetic leather industry is 2015/8/23